1. Preparing the Tape

Polypropylene Preparation: Polypropylene granules are melted and extruded into long tapes.

Spooling: These tapes are then wound onto large bobbins, preparing them for the weaving process.

2. Setting Up the Loom:

Warping: The vertical tapes, as the warp, are set up on the loom first. They are stretched out lengthwise and held under tension.

Spacing: The warp tapes are spaced evenly to ensure a uniform weave.

3. Weaving:

Introducing the Weft: The horizontal tapes, or weft, are then interlaced with the warp tapes using a shuttle.

Over and Under Pattern: The weft tapes are passed over and under the warp tapes in a systematic pattern, creating the weave.

Tightening the Weave: The newly introduced weft tape is pressed down tightly against the preceding weft tape, creating a compact fabric.

4. Inspection and Finishing:

Quality Check: The pp woven fabric is inspected for any defects or irregularities in the weave.

Cutting: The fabric is then cut from the loom once the desired length is achieved.

Finishing Touches: Depending on the intended use, the fabric may undergo additional finishing processes such as coating or treatment for added properties.

Applications of PP Woven Fabric

PP woven fabric, with its unique properties, is skillfully utilized in several applications. Let's explore some of these:

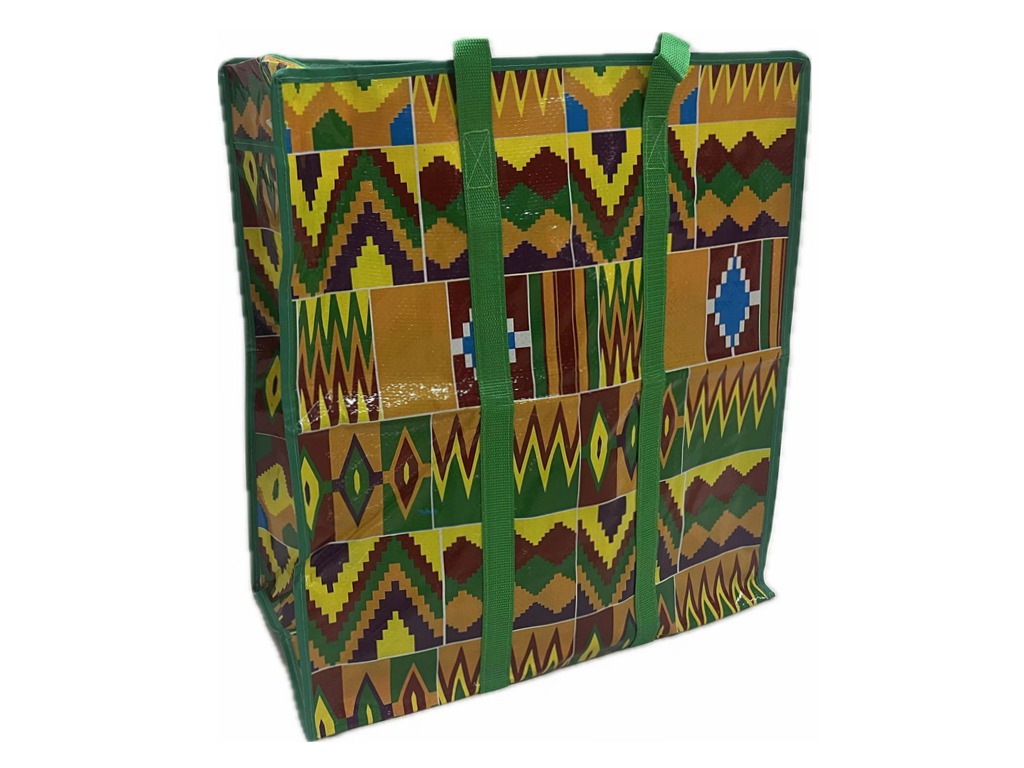

PP Woven Bags:

These bags are a staple in packaging, known for their strength and durability. PP woven bags can carry substantial weight, making them perfect for packaging food grains, fertilizers, and other bulk items. Their resistance to wear and tear ensures that the contents stay protected.

BOPP Bags:

Biaxially Oriented Polypropylene (BOPP) bags are a type of packaging that combines the strength of PP woven fabric with the visual appeal of a glossy finish. These BOPP bags are perfect for packaging products that require a clear and attractive appearance, such as retail items or food products.

Paper Polybags: By combining the tactile and visual appeal of paper with the strength of PP woven fabric, paper poly bags offer a sophisticated packaging solution. Often used in retail, these bags are sturdy, visually pleasing, and provide a high-quality feel.

Geotextiles:

PP woven fabric is used to create geotextiles, which are utilized in civil engineering to reinforce soil and promote proper drainage. These fabrics help stabilize the ground, making them essential in road construction and landscape engineering.

Construction Silt Fencing:

In construction sites, PP woven fabric creates silt fences that help control sediment runoff. These barriers prevent soil erosion and protect nearby water sources from pollution, showcasing the material’s environmental applications.

Landscape Covers: The durability and resistance of PP woven fabric make it suitable for creating protective covers for agricultural and landscaping purposes. These covers help protect crops from harsh weather conditions, pests, and excessive weed growth while allowing water and nutrients to seep through.

PP Woven Fabric Examples

Agriculture:

PP woven fabric is a trusted ally for farmers. Used as ground cover, it helps control weeds while allowing water and nutrients to reach the crops. Additionally, PP woven bags are perfect for packaging and transporting produce, ensuring that the goods reach the market in top condition.

Construction:

In construction sites, PP woven fabric takes on the role of a protector. It’s used in geotextiles to stabilize soil and improve drainage, ensuring a solid foundation for roads and buildings. Silt fences made from PP woven fabric also help manage sediment runoff, safeguarding the environment.

Food:

The food industry values PP woven fabric for its strength and resistance. PP woven and BOPP bags package various food items, from rice and grains to spices and pet food, ensuring that the products stay fresh and protected from external elements.

Chemical:

The chemical resistance of coated PP woven fabric is a boon for the chemical industry. It is used to create bags that safely transport powdered or granulated chemical products, such as fertilizers, without risk of contamination.

Mining:

In the mining sector, PP woven bags are invaluable for packaging and transporting mined materials. The bags’ durability and resistance to wear and tear make them suitable for handling rough and abrasive materials like ores and minerals.

Why Choose PP Woven Fabric

PP woven products bring a combination of practicality and efficiency. One of the key benefits of choosing these products lies in their durability. They are built to last, providing a reliable solution to wear and tear.

Another notable advantage is the cost-effectiveness of woven polypropylene. It provides a high-quality material without breaking the bank, making it the best option for various applications, from packaging to textiles.

Sustainability is at the forefront of many consumers’ minds, and woven polypropylene doesn’t disappoint. Polypropylene is recyclable, and its products can often be repurposed at the end of their life cycle, contributing to a circular economy and reducing waste.

So, opting for woven polypropylene products is a choice for reliability, affordability, and conscious consumption. It’s a material that aligns with the needs of today while keeping an eye on the future.

In conclusion, PP woven fabric emerges as a versatile and practical material that seamlessly fits into various industries, from agriculture and construction to food and mining. Its remarkable properties, such as strength, lightweight nature, and resistance to environmental factors, coupled with its cost-effectiveness, make it an invaluable choice. Additionally, its recyclability aligns with the growing demand for sustainable products.

By choosing PP woven fabric, consumers and industries are opting for a material that not only meets their immediate needs but also contributes positively to the environment. It’s a choice that combines quality, affordability, and responsibility, making it a preferred material for the present and the future.